Surge current protection using superconductor

Surge current protection

using superconductor

A Fault Current Limiter (FCL) is a device which limits the prospective fault current when a fault occurs (eg in a power transmission network). The term is generally applied to superconducting devices, whereas non-superconducting devices (such as simple inductors or variable resistors) are typically termed Fault Current Controllers. (For example, the ground fault circuit interrupter is commonly used in residential installations.)

Summary

Fault-current

limiters using high temperature superconductors offer a solution to controlling

fault-current levels on utility distribution and transmission networks. These

fault-current limiters, unlike reactors or high-impedance transformers, will

limit fault currents without adding impedance to the circuit during normal

operation. Development of superconducting fault-current limiters is being

pursued by several utilities and electrical manufacturers around the world, and

commercial equipment is expected to be available by the turn of the century.

Fault-Current Problem

Electric

power system designers often face fault-current problems when expanding

existing buses. Larger transformers result in higher fault-duty levels, forcing

the replacement of existing buswork and switchgear not rated for the new fault

duty. Alternatively, the existing bus can be broken and served by two or more

smaller transformers. Another alternative is use of a single, large,

high-impedance transformer, resulting in degraded voltage regulation for all

the customers on the bus. The classic tradeoff between fault control, bus

capacity, and system stiffness has persisted for decades.

Other

common system changes can result in a fault control problem:

·

in some areas, such as the United States

·

older but still operational equipment gradually becomes underrated

through system growth; some equipment, such as transformers in underground

vaults or cables, can be very expensive to replace

·

customers request parallel services that enhance the reliability

of their supply but raise the fault duty

Superconductive FCL

Superconductors

offer a way to break through system design constraints by presenting an

impedance to the electrical system that varies depending on operating

conditions. Superconducting fault-current limiters normally operate with low

impedance and are "invisible" components in the electrical system. In

the event of a fault, the limiter inserts impedance into the circuit and limits

the fault current. With current limiters, the utility can provide a

low-impedance, stiff system with a low fault-current level, as Fig. shows.

In

Fig. , a large, low-impedance transformer is used to feed a bus. Normally, the

FCL does not affect the circuit. In the event of a fault, the limiter develops

an impedance of 0.2 per unit (Z = 20%), and the fault current ISC is

reduced to 7,400 A. Without the limiter, the fault current would be 37,000 A.

The

development of high temperature superconductors (HTS) enables the development

of economical fault-current limiters. Superconducting fault-current limiters

were first studied over twenty years ago. The earliest designs used low

temperature superconductors (LTS), materials that lose all resistance at

temperatures a few degrees above absolute zero. LTS materials are generally

cooled with liquid helium, a substance both expensive and difficult to handle.

The discovery in 1986 of high temperature superconductors, which operate at

higher temperatures and can be cooled by relatively inexpensive liquid

nitrogen, renewed interest in superconducting fault-current limiters.

The emerging technology of FCLs has the potential to save money for utilities and increase efficiency for their customers by protecting equipment from damage and avoiding interruptions and outages. As the demand and sources for electricity rise, utilities are grappling with the challenge of more frequent and larger "fault currents."

Blackouts cost the

For instance, almost half of the states have mandates requiring the grid to handle significant boosts in the amount of energy from renewable sources such as solar and wind. These renewable energy sources are often connected in large numbers at specific locations in the electrical grid and can produce fault currents in excess of local limits.

Interest in advancing the use of FCLs is growing as utilities and the Department of Energy collaborate with manufacturers, national laboratories, and other stakeholders to modernize, expand and increase the capabilities of the nation's stretched-to-capacity electric grid. FCLs have the potential to play a pivotal role in transforming the current grid into the DOE's vision for a smart and more efficient grid.

During a ground fault, an FCL safely mitigates excess energy and prevents damage by switching to a high impedance state, which would normally affect utility transmission and distribution equipment.

Developed by ABB Corporate Research in Baden-Dättwil , Switzerland

Superconductive Fault-Current Limiter Concepts

The Series Resistive Limiter

The

simplest superconducting limiter concept, the series resistive limiter,

exploits the nonlinear resistance of superconductors in a direct way. A

superconductor is inserted in the circuit. For a full-load current of IFL,

the superconductor would be designed to have a critical current of 2IFL

or 3IFL. During a fault, the fault current pushes the superconductor

into a resistive state and resistance R appears in the circuit.

The

superconductor in its resistive state can also be used as a trigger coil,

pushing the bulk of the fault current through a resistor or inductor. The

advantage of this configuration, shown in Fig. is that it limits the energy that must be

absorbed by the superconductor.

The

fault-current limiter FCL normally is a short across the copper inductive or

resistive element Z. During a fault, the resistance developed in the limiter

shunts the current through Z, which absorbs most of the fault energy.

The

trigger coil approach is appropriate for transmission line applications, where

tens of megawatt-seconds would be absorbed in a series resistive limiter. The

trigger coillconfiguration also allows an impedance of any phase angle, from

purely resistive to almost purely inductive, to be inserted in the line.

The Inductive Limiter

Another

concept uses a resistive limiter on a transformer secondary, with the primary

in series in the circuit. This concept, illustrated in Fig. yields a limiter suitable for high-current

circuits (IL > 1000 A). One phase of the limiter is shown. A

copper winding WCu is inserted in the circuit and is coupled to an

HTS winding WHTS. During normal operation, a zero impedance is

reflected to the primary. Resistance developed in the HTS winding during a

fault is reflected to the primary and limits the fault.

The

inductive limiter can be modeled as a transformer. The impedance of this

limiter in the steady state is nearly zero, since the zero impedance of the

secondary (HTS) winding is reflected to the primary. In the event of a fault,

the large current in the circuit induces a large current in the secondary and

the winding loses superconductivity. The resistance in the secondary is

reflected into the circuit and limits the fault.

Fault-Current Limiter Applications

Fault-current

limiters can be applied in a number of distribution or transmission areas.

Three main applications areas are

1.

. Fault-current limiter in the main position. The fault-current

limiter FCL protects the entire bus

2. Fault-current limiter in the feeder position. The fault-current limiter

FCL protects an individual circuit on the bus. Underrated equipment can be

selectively protected as needed in this manner.

3 Fault-current limiter in the bus-tie position. The two buses are tied, yet a

faulted bus receives the full fault current of only one transformer.

. Fault-current limiter in the

main position. The fault-current limiter FCL protects the entire bus.

The

most direct application of a fault-current limiter is in the main position on a

bus (Fig. ). Benefits of an FCL in this application include the following:

·

a larger transformer can be used to meet increased demand on a bus

without breaker upgrades

·

a large, low impedance transformer can be used to maintain voltage

regulation at the new power level

·

I2t damage to the transformer is limited

·

reduced fault-current flows in the high-voltage circuit that feeds

the transformer, which minimizes the voltage dip on the upstream high-voltage

bus during a fault on the medium-voltage bus

Fault-current limiter in the feeder position. The fault-current

limiter FCL protects an individual circuit on the bus. Underrated equipment can

be selectively protected as needed in this manner.

TRANSFORMER

An

FCL can also be used to protect individual loads on the bus (Fig.). The

selective application of small and less expensive limiters can be used to

protect old or overstressed equipment that is difficult to replace, such as

underground cables or transformers in vaults.

. Fault-current limiter in the

bus-tie position. The two buses are tied, yet a faulted bus receives the full

fault current of only one transformer.

40MVA

TRANSFORMERS

LOAD

An FCL can be used in the bus-tie position (Fig. ). Such a limiter would require only a small load current rating but would deliver the following benefits:

· separate buses can be tied together without a large increase in the fault duty on either bus

· during a fault, a large voltage drop across the limiter maintains voltage level on the unfaulted bus

HTS

LEADS

HTS

current leads represent the first large-scale application of high temperature

superconductivity. This has occurred because even modest current density HTS

material can be used to provide a significant reduction in the parasitic heat

conducted into a cryogenic environment via the electrical leads used to provide

current to the device. Fig. illustrates

a typical application.

Fig. . A conduction-cooled HTS magnet system used for magnetic separation, illustrating the use of HTS current leads to reduce heat load (LANL).

There

are three classes of applications where HTS leads are seeing rapid

introduction:

1. high current LTS magnets cooled

by liquid helium

2. conduction-cooled LTS magnets

3. conduction-cooled HTS magnets

HTS Lead Technologies

There

are two basic technologies for HTS leads: bulk rods of ceramic superconductor,

and metal matrix superconducting composites. Both have developed to the point

that they are offered for commercial sale. There are advantages and

disadvantages to each.

Bulk

ceramic leads

: are made by a variety of methods and of a number of different HTS materials,

but the primary objectives are the same: to achieve a rugged ceramic structure

with high critical current and low-resistance connections. The advantage of

this approach is that the ceramics have intrinsically low thermal conductivity,

so that leads may be made quite short for easier integration in the system. The

disadvantages are that the ceramic rods are susceptible to breakage during

installation, during operation, and (like the bulk structures used in

fault-current limiters) during temperature excursions caused by driving the

lead normal. In addition, it has proven difficult to provide very low

resistance connections between the ceramic superconductor and the metallic

connections at the ends of the leads. These disadvantages have been mitigated

by careful system design in a number of magnets, and successful systems have

been built using bulk leads.

Metal

matrix composite leads : essentially use the powder-in-tube technology used for BSCCO

wire to manufacture a wire or tape incorporating a low thermal conductivity

metal or alloy in place of the customary silver matrix. This approach has

employed only Bi-2223 superconductor. The advantages of metallic leads are

intrinsic ruggedness, high tolerance to thermal excursions, and very low

contact resistances. These advantages are to be balanced against the

disadvantage of the somewhat higher thermal conductivity of the composite

material, which requires that a longer lead assembly be used to achieve heat

leaks comparable to bulk leads.

QUENCHING OF SUPERCONDUCTORES

A

superconductor when operated with in a certain temperature and external

magnetic field range

critical temperature –Tc

critical magnetic field-Hc

exhibits no electrical resistance if the current flowing through it is below a

certain threshold critical current level –Jc and is said to be in

superconducting state

However

if the current exceeds this critical current level the superconductor will

undergo transition from its superconducting state to a normal resistive state

takesplace .this transition is termed as quenching.

Development

FCLs are under active

development. In 2007, there were at least six national and international

projects using magnesium diboride wire or YBCO tape, and two

using BSCCO-2212

rods. Countries active in FCL development are Low temperature superconductors cannot be used for commercial FCLs as the AC losses at liquid helium temperatures mean that the cryogenic cooling cost makes the whole device uneconomic.

First applications for FCLs are likely to be in electric-drive ships: naval vessels, submarines and cruise ships. Many more FCLs will eventually be used to help control land-based electricity distribution and transmission systems.

|

World's highest-rated superconducting current limiter |

||

|

1.2 MVA SCFCL in powerplant "Löntsch" (

|

|

|

|

The

new current limiter is the world's first superconducting device to go into

service in a power plant. The prototype was installed in the Löntsch

hydropower plant, near Glarus in central

|

||

Japanese FCL Program

The

driving factors for current limiters in Japan

are somewhat different from those in the United

States , given that IPPs and cogenerators are not as

prevalent in Japan Japan Japan

In

response to this real market pull there has been a series of programs to

develop fault-current limiters using a variety of methods, with recent focus on

superconducting limiters (Nakade 1994). Although FCLs are not a component of

the NEDO budget, TEPCO has reported that it spends about ¥100 million per year

(~$1 million) on this program, and some resistive FCL work is apparently

included in the NEDO budget under the topic "Research of Superconducting

Materials and Devices."

In

the late 1980s, Seikei

University

Mitsubishi

Electric Company (MELCO) has been participating in a MITI/NEDO FCL program

since 1990. This is a resistive limiter approach using HTS films on a strontium

titanate substrate that has demonstrated limiting of 400 A currents to 11.3 A.

The Central Research Institute of the Electric Power Industry (CRIEPI) has

developed the inductive limiter shown in Fig. 4.11 (Ichikawa and Okazaki 1995).

This approach, similar to those of ABB and Siemens-Hydro Quebec, uses a

cylinder of bulk BSCCO-2212 or BSCCO-2223 to separate a normal copper coil from

an iron core. In normal operation, the field from the copper coil does not

penetrate the superconductor; under fault conditions, however, the current

induced in the superconductor is sufficient to drive it normal, and the

magnetic field links the iron yoke. This greatly increases the inductance of

the copper coil, thus providing current limiting. CRIEPI work has focused on ac

magnetic shielding performance of bulk superconductors and their responses to

fault currents. In addition, introduction of a "control ring" in the system

to absorb some of the energy deposited during a fault has reduced the cooldown

time of the shield following a faulted state.

. Schematic diagram of the CRIEPI

inductive FCL (Ichikawa and Okazaki 1995).

The

most extensive FCL program in Japan

As

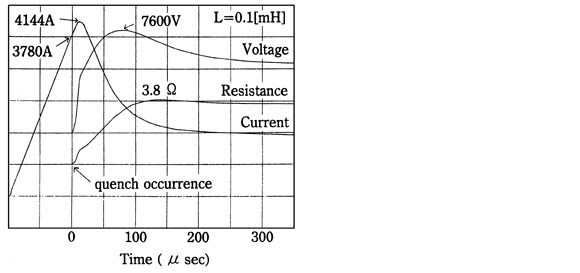

shown in Fig. , the FCL is formed by connecting four superconducting coils in a

series-parallel configuration so the total inductance is minimized. One set of

coils is used for each phase of the device, and limiting is accomplished by

quenching the coils. The current version of the FCL shown in Fig. 4.13 uses a

special low ac loss Nb-Ti conductor. Tests in a circuit with a nominal short

circuit current of 25.8 kA have successfully demonstrated limiting to about

4,000 amps

Fig. 4.13. Exterior view of the 6.6 kV 2,000 A-class current limiter. The coil is 420 mm in diameter and 640 mm long (Nakade 1994, 35).

Current limiting

characteristics of Toshiba FCL shown in Fig. 4.13 (Nakade 1994, 35).

Recent

work has included the introduction of HTS current leads to reduce the

refrigeration load of the system to levels that can be handled by a 4 K Gifford

McMahon refrigerator. Over three generations of the device, the heat leak has

been reduced from 13.8 watts to 3.4 watts, which is nearing the required level.

Conclushion

Electric

power disruptions cause hundreds of millions of dollars worth of economic loss

every year to the world’s leading economies. Worldwide energy demand is

increasing rapidly, requiring new solutions to dramatically improve the

reliability of our energy supply. Fault Current Limiters are new devices, using

the unique electrical properties of HTS to almost

instantaneously protect power grids against short circuits and thereby prevent

costly outages. They are a key member of a family of ultra-fast HTS devices and

machines used for conditioning electrical power.

Benefits

In comparison to conventional technology, HTS fault current limitters provide

- Over 100 times faster response time

- 10 to 20 times shorter recovery time

- Time-adjustable response functions

- 1000 times the number of full-power

protection cycles

THANKS... REALLY HELPFUL

ReplyDeleteThis comment has been removed by the author.

DeleteThis comment has been removed by the author.

Deleteits simply good and really usefull..

ReplyDeletesgsd

ReplyDeleteYour ideas are very useful. Actually one of my friends is planning to work in this field, so I’ll definitely recommend your post to him. Many thanks to you. Thin Film Coatings From Valley Design.

ReplyDeleteYour post on power surges is an eye-opener. The potential threat to our electronics is often overlooked, and your insights provide essential information.

ReplyDelete